In a groundbreaking development at MIT, engineers have unveiled a game-changing membrane that could potentially revolutionize the process of crude oil fractionation. The innovation involves filtering the components of crude oil based on their molecular size, marking a significant departure from traditional methods. This novel approach aims to significantly decrease the energy consumption involved in separating crude oil components.

“This is a whole new way of envisioning a separation process. Instead of boiling mixtures to purify them, why not separate components based on shape and size? The key innovation is that the filters we developed can separate very small molecules at an atomistic length scale,”

expressed Zachary P. Smith, an associate professor of chemical engineering at MIT and the senior author of the research.

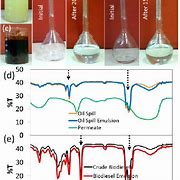

The newly developed filtration membrane boasts remarkable efficiency in segregating heavy and light components from crude oil while demonstrating resistance to swelling—a common issue encountered with other existing oil separation membranes. Comprising a thin film that can be easily manufactured using established industrial processes, this membrane holds promise for scalability and widespread adoption.

Taehoon Lee, the lead author of the study and a former MIT postdoc who currently serves as an assistant professor at Sungkyunkwan University in South Korea, emphasized the transformative potential of this technology. Their findings were published in Science journal.

Conventional methods for fractionating crude oil typically rely on heat-driven processes, constituting approximately 1% of global energy consumption. Through utilizing membranes for crude oil separation, it is estimated that energy requirements could be slashed by as much as 90%. For this innovative approach to succeed, it necessitates a membrane that facilitates rapid hydrocarbon passage while selectively filtering compounds based on their sizes.

Unlike previous efforts centered around polymers like PIM-1 for hydrocarbon filtration—which tend to absorb organic compounds excessively leading to swelling—the MIT team sought inspiration from reverse osmosis water desalination polymers known for their energy-efficient properties since the 1970s.

By modifying these polymers used in water desalination processes through interfacial polymerization techniques, researchers successfully tailored them to cater specifically to separating hydrocarbons present in crude oil. The alteration involved changing the bond between monomers from amide to imine—a more rigid and hydrophobic connection enabling swift hydrocarbon traversal without detrimental swelling effects typically seen in polyamide films.

“The polyimine material has porosity that forms at the interface…those pores no longer swell like other materials,”

explained Smith regarding the enhanced characteristics achieved through these modifications alongside incorporating shape-selective molecules like triptycene into the design.

Upon testing with standard benchmark mixtures such as toluene and triisopropylbenzene (TIPB), researchers observed an impressive concentration boost in separated components—a testament to its efficient performance capabilities. Moreover, when applied to industrial mixtures comprising naphtha, kerosene, and diesel compounds, it effectively distinguished between heavier and lighter molecules based on their molecular sizes.

The potential industrial applications are vast—envisioned as multiple filtration stages working sequentially akin to refining steps—to concentrate desired products efficiently throughout each phase.

“You can imagine…using different membranes…to purify complex mixtures [and] isolate chemicals,”

highlighted Smith regarding its practical implications.

With interfacial polymerization already well-established for water purification membranes—an advantage leveraged by adopting similar chemistries—mass production feasibility becomes increasingly promising according to Lee’s insights. This pioneering research received partial funding support from ExxonMobil via the MIT Energy Initiative.

MIT’s trailblazing work signifies a major stride towards sustainable energy practices by significantly reducing energy consumption associated with crucial industrial processes like crude oil fractionation—an innovation poised to reshape conventional methodologies while paving the way towards more eco-friendly solutions within critical sectors globally.

Leave feedback about this